|

The history and introduction of the YXLON

YXLON International is an innovative High-Tech company, rich in great traditions.

Although still young as a company, we can look back on many years of experience in x-ray based non-destructive testing. The merger of Philips Industrial X-Ray and ANDREX A/S founded YXLON International in 1998. Shortly after LumenX and in 2003 HAPEG GmbH were acquired and incorporated into YXLON International. Each company brought in its specific knowledge and experience enabling YXLON International to offer its customers a wide range of products and services.

Whether in ship-and vessel construction, the automotive, electronics, aircraft or food industry, YXLON International is based on its long experience - offering solutions, which fit in any manufacturing process to guarantee highest quality and safety standards for industrial products.

International is the leading supplier in X-ray area. Produce the first portable X-ray equipment¡B mobile X-ray equipment¡B X-ray tube from C.H.F. Müller¡Bmetal-ceramic tube-160 kV¡BFirst 450 kV tube in the world. And XYLON still engages in searching and developing constantly.

We would like to introduce the X-ray to you as follows.

1. Components

provides not only critical components like tubes, generators and detectors, but also accessories required for your specific application such as superior displays for radioscopy. We are your expert partner for all your industrial X-ray needs.

2. Systems

If you want to inspect thick walled steel welds or thin walled cast aluminum parts, to look for corrosions or to check if the assembly is complete - only the maximum precision and safety guarantees success. YXLON¡¦s X- ray systems will help you fulfill these tasks. As a stationary, mobile or portable system, used in fully automated radioscopic applications or in nature, YXLON has the solution for your specific demands.

3. Suitable machines for tire industry:

3.1. XLON.MTIS - Modular Tire Inspection System

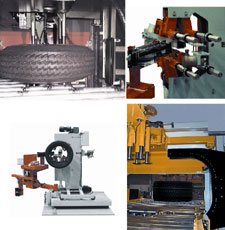

YXLON Modular Tire X-ray Inspection System

The MTIS Modular Tire Inspection System was developed to meet the specific needs of the global tire industry. Whether you are inspecting passenger or truck tires, the MTIS modular design allows the unit to grow to meet your ever changing inspection demands while keeping your monetary investment at a minimum.

High Performance Inspection Capabilities

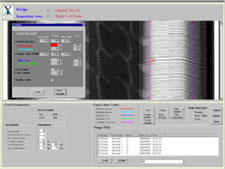

YXLONs Linear Diode Array Imaging System is designed for viewing the most stringent spatial resolution and contrast sensitivity requirements consistent with ASTM Specification F-1035. It resolves all synthetic tire cord materials, not just steel. Clear, high resolution images of low-density materials such as aramid, nylon, and polyester enable the operator to easily identify anomalies such as:

? Crossed and Broken Body Ply Cords ? Body Ply Cord Spacing, Turn-Ups and "S"ing ? Chafer Dimensions ? Belt Step-Off and Concentricity ? Open and Heavy Splice ? Bead Bundles Concentricity ? Material Voids and Porosity ? Foreign Material

The entire MTIS product range is designed to accept a wide range of tire sizes and constructions while keeping small space requirements.

Including YXLONs 16bit based image enhancement program the MTIS offers state of the art technology to provides fast and reliable results.

3.2. YXLON.Mini-OTR

Off-Road Tire X-ray Inspection System YXLON¡¦s Off-Road Tire X-ray Inspection System offers superior material handling and high resolution imaging for reliable, advanced quality assurance techniques. The sidewall, bead, air retaining liner, tread, plies, and belts of off road tires can be inspected for foreign materials, body ply cord spacing, turnups, chafer height, and bead bundle concentricity. 3.3. YXLON.AXIS for Tires

Automatic X-ray Inspection System AXISTM Automatic X-ray Inspection System is the next logical step in the evolution of tire X-ray inspection. AXISTM provides fully automatic tire inspection for consistent, repeatable inspection. Pass/Fail decisions can be made without operator intervention. AXISTM proprietary software is Windows NT-based for easy set up and use. Six types of test can be preprogrammed for automatic inspection of body cord, sidewall, belt, turnup, and bead area. ¡@ Tests Performed: ¡@ ? Body Cord Area for open ply splices, narrow body ply cord, crossed or doubled cord, open or broken cord, and wild wires ? Belt Area for bad belt alignment, foreign material, minor dog ear, and tread lug blisters ? Turnup for dog ear ? Chafer for open splices and high misplacement AXISTM

3.4. YXLON.MU2000 Tire on Wheel

Tire-on-Wheel Inspection Whether in development, design, manufacturing process or accident investigation, the requirements for X-ray inspection of wheel-tire assemblies are steadily increasing. The YXLON International MU2000 Cabinet X-ray Inspection System is especially suited for the inspection of wheel-tire assemblies to ensure a 360¢X seal between a tire¡¦ s bead and the wheel to which it is mounted. Furthermore, the inspection for tread separation, belt gull wing, deviations in liner, sidewall or tread thickness, and 360¢X tire component placement can be easily performed. The wheel-tire assembly is positioned on a roller block, which can be horizontally moved. X-ray tube and image intensifier are mounted to a C-arm, capable of up and down movements and tilting. This concept of manipulation ensures all necessary views of the inspection sample. The X-ray cabinet system complies with the regulations for fully protected X-ray shielding according to the Deutsche Röntgenverordnung (German X-ray law). The Image Intensifier system ensures real-time inspection with an excellent resolution and dynamic images. As an option the image enhancement and archiving systems IMAGE.2500i or IMAGE.2500i-R can be integrated for image processing and storing. 3.5. Improve Performance of Older Tire X-Ray Systems

For many years, YXLON and its predecessors have designed and manufactured tire X-ray inspection systems. These systems were built to last and many are still operating today. Over the years, however, technology has advanced and some key components have become obsolete.

Several retrofit and upgrade solutions are available to update older tire X-ray inspection systems. YXLON¡¦s Linear Diode Array Imaging Systems, for example, are excellent replacements for Isocon-based cameras. A retrofitted system offers an impressive return on investment with better images, faster inspection times, and reduced risk of extended down time.

Extend the life of your tire X-ray inspection system. Get today¡¦s state-of-the-art technology without buying a new system or interrupting your current workflow. We know your machine, and we can design the exact retrofit package you need.

|