|

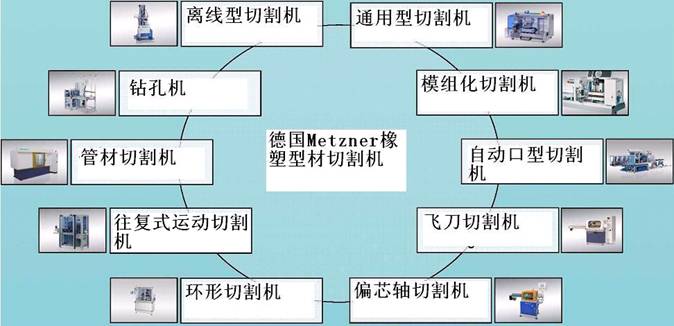

Metzner maschinenbau GmbH specilized produces rubber cutting machine, which has 25 years research and development in this industry. As a world leading company, Metnzer bought the pioneer research and development cutting machine company, turns to history of hundred years---Max muller. Metzner offers devices to many big manufacturers among different industries, becomes outstanding successful in the world.

Metzner coorperates with Metzeler, Hutchinson, GDX, Cooper Standard etc. to develop projects upon long-term strategic partnership, which proves its authority, superior and stable function. It must be helpful to improve products quanlity, seize customer abroad and home, rank the top-one enterprise.

Metzner rubber cutting advantage

Precision. Mandrel tublar’s cutting precision can be at tolerance of +/-0.01mm

Operation system gets effective control, highly automatic management, configuration’s automatic recognition can automatic responsive, one people can easily control the whole factory’s cutting. It adjusts cutting requirement with set data, and re-installation can be done within 20mins with reducing man-made interference factor.

Cutting machine can be customized, you have multiple options of spare parts for installation.

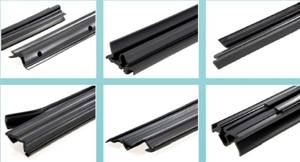

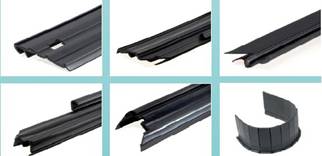

We have professional technician in China, answer and solve the relative questions and problems any time and any place, to help you leave away worries. These are partial diagrammatic of cutting rubber mold, includes soft mold and hard material mold with frame. Different cutting blade are for different products, the same for cutting way, which can get re-installation.

Features of design

When cut on mold with frame, measure and control postion can scan to gap part of mold without frame automatically, which makes section more neat and nice. Without polishing such repeat procession, it saves time, improve production capacity, gains competative for products.

We do customized drilling either on-line cutting, or off-line cutting or moving cutting. Trash is recycled with special design, it won’t be mixed with products. It ensures cutting

It cuts soft mold and hard material mold with frame. When cut mold with frame, kinfe can shift with mold followed. Imput’s motor is operating with cutting with stopping at the same time, which prevents upwarp, distortion of mold with frame with too faster imput, then effects cutting precision several problems.

Design for fast extrude speed and small prodcuts( max 50mm). Flying knife cutting can be 15 cut/ seconds, 850 cut/ mins, 51000 cut/hours, precision at tolerance of +/-0.1mm。

|