|

MAPLAN is a member company of the STARLINGER GROUP. It has steadily risen to rank among the top two supplies of rubber injection presses in the world. This meteoric rise is the result of MAPLANˇ¦s meticulous attention to customersˇ¦ needs both in technical detail and personal service requirements. The technology of FIRST-IN-FIRST-OUT and Maplan 2K( the double nozzle system can inject two materials for compound at one time for example for double color seals) represent the most advanced ideal in the world. MAPLANˇ¦s machinery has been used in a lot of rubber products plants and rubber fittings products factories for tyre industry. For example: HUTCHINSON GROUPˇBFREUDENBERG GROUPˇBPARKERˇBWOCOˇBSTANDARD COOPER PRODUCTS / Nishikawa GroupˇBGUMMI-METALL-TECHNIKˇBTRELLEBORG / FORSHEDA / DOWTYˇB THE WEST COMPANY (Pharmatech), etc.

Introduction of MAPLANˇ¦s machines:

1. Types

Ÿ vertical model Ÿ horizontal model Ÿ C-frame design

vertical model horizontal model

C-frame design 1. Basic specification range:

? Injection volume: 50~26.000 CM3 ? Clamp force: 15~1.000 Tons

2. Advantages of Maplan machines

? clamp system

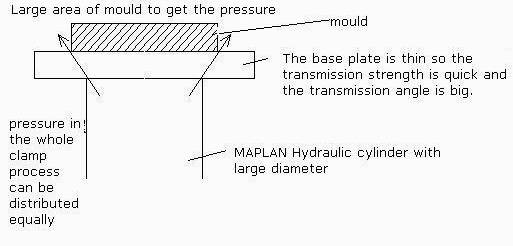

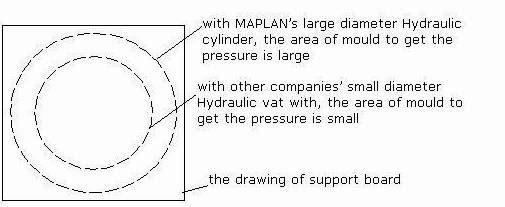

(1) With the large size of the hydraulic cylinder, the pressure in the clamp process can be distributed equally. The area of mould to get the pressure is large and can get the pressure highly equally. The MAPLAN machine is the only machine reaching this high level of exact parallelity.

Maplan design:

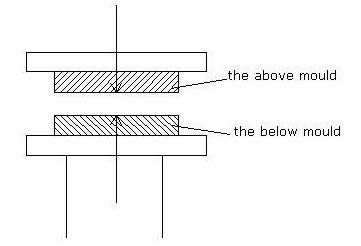

(2) The middle of the mould on the below moulding board get the pressure larger than around, so the middle of the mould is bended very slightly. Considering of the above situation, MAPLAN designed a suitable above injection unit, using the strong injection pressure to give a counterforce to counteract the transmogrification in order to reduce the coarse products.

? Injection system

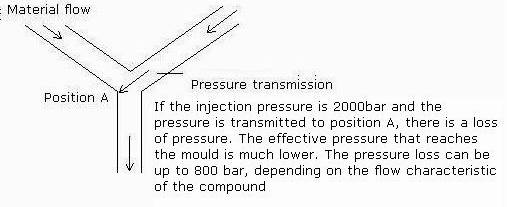

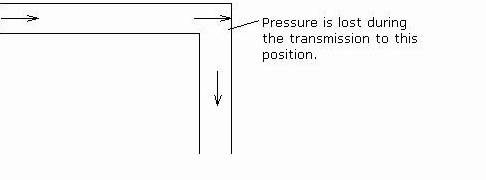

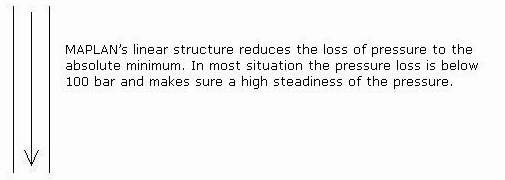

(1) Maplan 2K: the double nozzle system can inject two different kind of materials at one time, as for double color seals. This represents the most advanced technology in the world. (2) The technology of FIRST-IN-FIRST-OUT: this principle makes sure that the material which is delivered into the screw first is injected into the mould first. (3)The pressure loss during the injection process is small. There are the three different principles as follows:

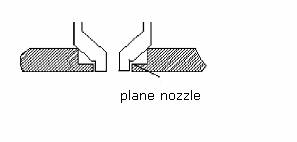

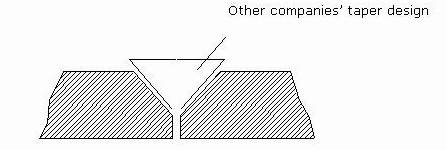

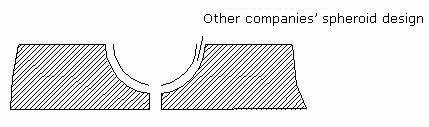

A plane nozzle is a tight nozzle because there is nearly no wear and tear. If a conical or round nozzle is positioned just a little bit out of the center the result is wear and tear and leakage. If a plane nozzle is position a little big out of center there is still no problem. Because of this fact a plane nozzle is tight nozzle.

? Control system:

PC4000, Maplan control generation 4, advanced user friendly technology. The system is structured in a modular manner which can be adapted to individual customer requirements.

This means:

(1) high repeatability and accuracy to improve the quality of the products (2) rapid speed, short cycle times to improve the efficiency of product (3) multi tasking operation system for fastest and time constant calculations

- internal memory for 50 parameter sets minimum = PC400plus, PC4000plus unlimited - customised page - special machine cycle like OMI, bumping, vacuum, etc - free cycle configuration - multi profile for injection, closing and opening - integrated PID control for temperature zones - plasticizing ramp for most accurate injection volume - electronic back pressure control

PC4000 features user friendly ˇ§Windows-likeˇ¨ graphics. Display pages are simplified resulting in ease of operation and elimination of operator confusion.

The operation and parameter input is simplified by the utilization of three dimensional colour graphics. Interface language is available in Chinese.

The controlˇ¦s large capacity capability for arithmetic processing is best utilized by an operating system which is capable of multitasking. The arithmetic power is carefully metered and the control algorithms are processed in a time constant way. This results in an extremely accurate repeatability of process parameters.

? Complete assistant equipments

MAPLAN provides complete assistant equipments for customers so that it can accommodate to various production conditions. They provide a special hydraulic pressure device for separating the moulds in two sides of machine and hydraulic mould run out device and strip intake device etc.

? Maplan diagnostic

By means of the unique self diagnostic system MAPLAN-Diagnostic, the recognition and elimination of faults is a childˇ¦s play. If a fault occurs the machine automatically displays the reason for the selected movement and prompt measures to eliminate the fault.

|

|

|

ˇ@ ˇ@ |

ˇ@ |

|

|