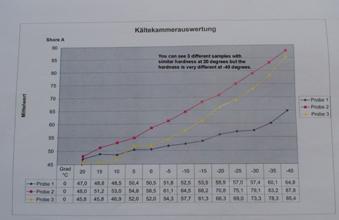

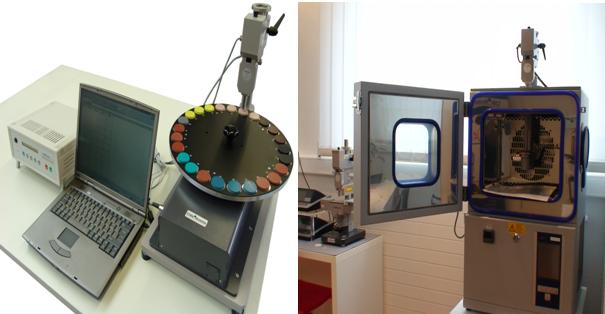

Bareiss company developed the hardness tester with wild temperature range test condition which special for tire manufacturer, it is special design for the R&D department of tire company. The advantage as follow: 1. The machine was designed and developed by cooperation Bareiss together with Continental, Michelin, Good year, for a 3 years period of confidential, this special machine can not be published on the market. Until now the period was expired therefore we can allowed to introduce to the customer in the world. Further more, Bareiss integrate the individual function of separate tire company. And now present the best machine for R&D department. 2. the machine designed for the temperature condition from -40 to 100ĒJ inside the chamber, which possible to measures the hardness of sample and finish product in the same time, and display the curve of hardness. Most of tire manufacturers only measure the Shore A hardness which also called sample piece hardness, but in fact the actual performance of hardness is the hardness of finish tire. The value of finish tire hardness degree is meaningful for the finish tire on the different temperature conditions, for example winter tire or the tire in the area of Africa and Mideast for high temperature. (Demand of Continental). 3. The machine measures the different position/ part of a tire on temperature range -40~100ĒJ, the value and curve as picture 1. The machine equipped with a rotate table which able for up to 25 pieces of testing sample. Which allowed to show the 25 values of different pieces on different temperature. It provides the possibility to analysis the hardness relationship and variation between each other. (Demand of Goodyear) ?? 4. The machine can measure the IRHD hardness (finish product) & Shore A hardness in the same time by one machine with? exchangeable test device. Which provide the possibility for comparing the result of IRHD& Shore A and analysis the relationship between each other. It helps the developing of quality control. (Demand of Michelin) 5. Base on the analysis data by R&D department, the QC people can take the sampling on site and feed back to the laboratory or QC control department. Which able to monitoring the quality of tire on time.

Picture 1: you can find the 3 compoundsĄĶ hardness variation from +20~-40ĒJ, 3 compounds hardness are very close when the temperature on +20ĒJ. Along with the temperature rise up, the hardness shows bigger difference on 3 compounds. The maximum 90 degree, minimum 65degree.

Picture2: application of Continental, machine design allowed to measures the different position/ part of tire, and working with IRHD and Shore A in the same time. We can combine the hardness tester with temperature chamber which allowed get up to 25 testing pieces on temperature range -40~+100ĒJ |