|

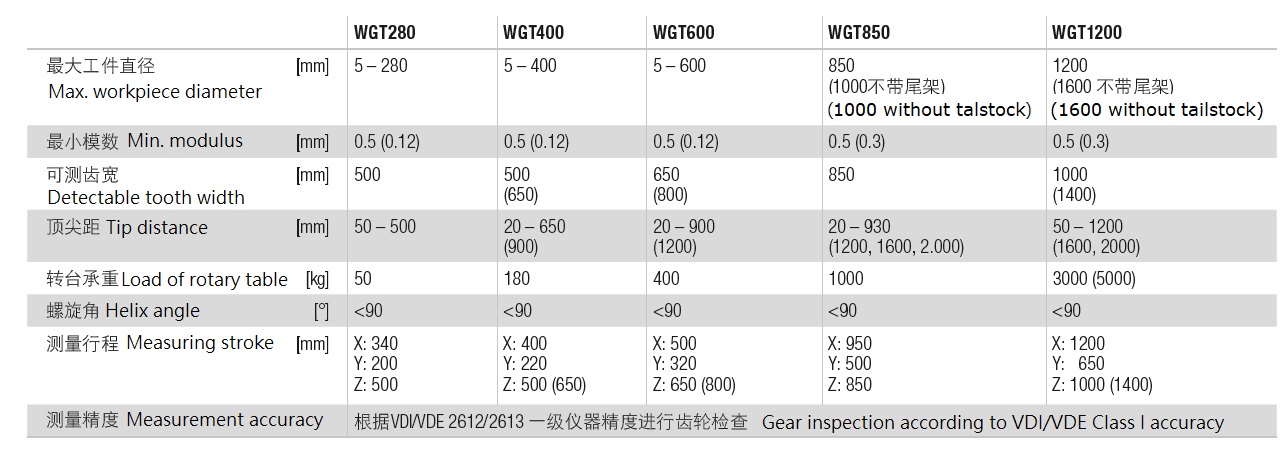

The 4-axis measuring instruments of the WGT series have high-precision mechanics and electronics, which are controlled by smart software. Machines for gear inspection must fulfil even stricter specifications than machines for gear manufacturing: they comply with the VDI guideline VDI/VDE 2613, group 1. The WGT machine is not the solution – it is part of the solution. The application team examines the specific requirements and then configures a system that fulfils them. Gear inspection machine options include travel ranges on the Z-axis adapted to customer requests, longer tailstocks for mounting longer shafts and various rotary tables for the right load capacity. An automatic probe change system ensures uninterrupted measurement of the workpieces. Thanks to its wide range of accessories, a WGT machine can be perfectly adapted to meet customer requirements and individually configured. It is suitable for all types of gears, such as cylindrical gears, bevel gears, worms, worm wheels, shafts, gear cutting tools and other rotationally symmetric parts. All machines are equipped with Renishaw probes. They offer the highest precision at low operating costs. The international Renishaw team supports customers and Liebherr and is responsible for the global supply of spare parts, probes and accessories as needed.

|