|

Each design is just to bring you higher production quality and efficiency!!! Equipment features: 1. Professional double-shaft head design ensures the stability of the equipment and the high-quality production quality of customers!! Liebherr Gear grinding machine adopts double grinding head design. Compared with other models on the market, only single grinding head can make the whole grinding shaft more stable, so the accuracy is more stable, and customers can produce higher quality and stable workpiece!

2. The forming mill and worm mill can be used in the same equipment to reduce the overall investment of customers and meet the requirements of customers for proofing and batch production! The equipment has a unique double grinding head design. Both the forming mill and the worm mill can be used. The forming mill is used for the proofing of the workpiece, and the worm mill is used for the mass production of the workpiece. One equipment can meet the two needs of customers, so one equipment can meet the requirements of customers for the proofing or mass production at the same time, reducing the overall investment!! |

|

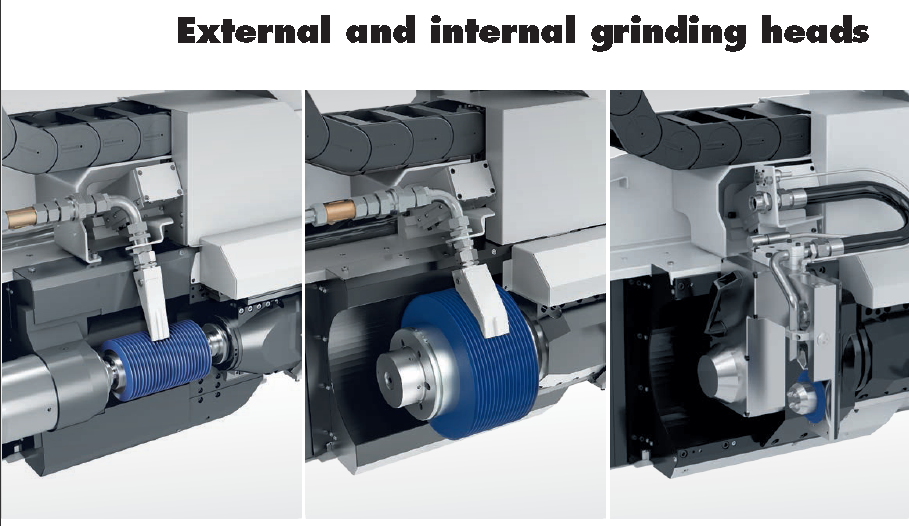

| 3. Unique grinding head design, which can use smaller diameter grinding wheel without interference, can replace the function of quilting, and the process range is wider!!

The unique grinding head design allows the equipment to use the conventional large-diameter grinding wheel in addition to the equipment's mandrel and grinding wheel, and can use the small-diameter worm grinding (baby worm) 60mm, and even achieve the function of replacing the quilted teeth. Our model conforms to the noise requirements of the electric drive, which is a R&D model with powerful functions, far faster beat than the opponent, stable accuracy, the most suitable four-piece set for producing new energy, and accurate positioning!!

4. The equipment can meet the process requirements more widely, and it can also make the customer's equipment more flexible and maintain stable product production! Because the equipment can meet the three different functions of forming mill, large-diameter worm mill and small-diameter worm mill at the same time, the customer can flexibly deploy the equipment, and the equipment limitations of other competitors will not cause one equipment to only produce the corresponding workpiece. In the future, if the specific equipment fails or needs to be repaired, the whole production will stop!

5. There are no defects of other competitors' equipment, which can meet customers' more technological needs! A competitor's KXXX equipment does not have the function of grinding internal teeth, and the use of small diameter worm wheel grinding will have interference problems. Liebherr (Liebherr) gear grinding machine has the function of grinding internal teeth and has no interference problems! |