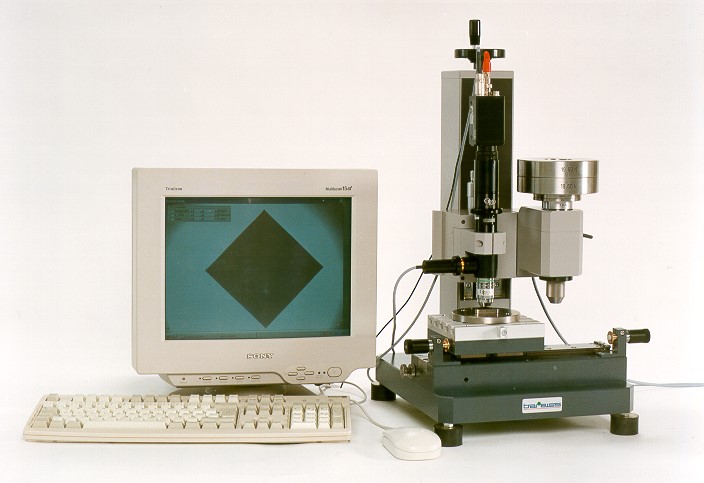

Bareiss Low Load Hardness Tester "V-Test"

With a new convincing concept Bareiss is bringing the low load hardness tester V-Test on the market. Each, the loading unit and the measuring system are in a fixed position. The test specimen is placed on a precision sledge which can be moved and positioned very precisely. The user will have two important advantages: 1. On the one hand he can see the test specimen without any problems when positioning. 2. On the other hand the impression of the Vickers indenter is appearing accurately under the measuring system and does not have to be searched in a complicated manner. The test- and measuring run needs less time and faulty measurements are avoided. Besides the moved mass is reduced for about 90 per cent. The V-Test was developed especially for the increasing requirements to the documentation obligation and the fast, rational examination of work pieces. A solid machine body is carrying the loading unit, the positioning sledge and the measuring system. Motor control, voltage supply etc. are in a 19"-table housing. The electromagnetically driven loading unit can be delivered in two versions: As a low-load-version in the range of HV 0,1 up to HV 10 kp as well as a micro-version in the range of HV 0,01 up to HV 2 kp. The test load is applied by dead loads. The volume of delivery comp rends alternatively a set of loads for "low load" and/or "micro". A Vickers diamond is used as an indenter. The indenter is arranged in this way that the test specimen is not damaged while it is placed. The precisely moving manually or automatically positioning sledge is carrying a magnet table for the fixation of the test specimen. Magnets at both ends provide for a constant contact and reliable results. The comfortable video measuring system with a CC camera of a high resolution possesses a highly exact zoom shot optics with a twenty-way basic optics and 7 rest positions. A magnification of 2000 times is possible without the need of exchanging the objective. A grabber card and two software modules for statistics, SPC and histogram as well as for hardness process measurements belong to the video measuring device. The measured values can be stored for further processing and for statistical evaluation. Optionally you can have an XY-table, digital micro meter screws with connection to PC as well as several fixing and clamping devices. Besides you can have a DKD calibration in company Bareiss. |

|

|

¡@ ¡@ |

¡@ |

|

¡@ |

|